Mastering Chain Link Fence Panel Connectors: A Comprehensive Guide

Chain link fences offer a durable and cost-effective solution for security and boundary definition. A crucial element in their assembly and longevity lies in the quality and appropriate use of chain link fence panel connectors. These connectors are the unsung heroes that bind the fence sections together, providing strength, stability, and a clean, professional appearance. This guide delves into the world of chain link fence panel connectors, covering everything from types and materials to installation techniques and maintenance tips.

Understanding the Importance of Chain Link Fence Panel Connectors

Chain link fence panel connectors are not merely accessories; they are integral components that determine the overall integrity of the fence. Poor quality connectors or improper installation can lead to sagging, instability, and even complete fence failure. Investing in high-quality connectors and understanding how to use them correctly is essential for creating a fence that will withstand the test of time and environmental factors. The right chain link fence panel connectors ensure that your fence provides the security and peace of mind you’re looking for.

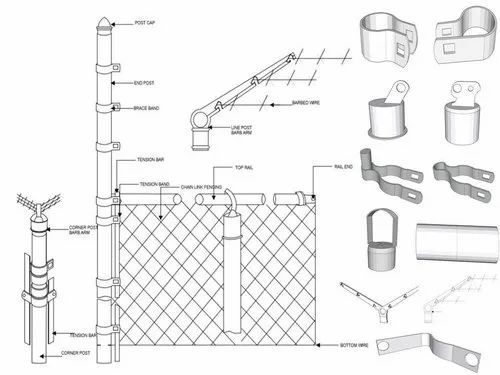

Types of Chain Link Fence Panel Connectors

Several types of chain link fence panel connectors are available, each designed for specific applications and fence configurations. Understanding the differences between them is crucial for selecting the right connectors for your project.

Line Rail End Connectors

These connectors are used to attach the top and bottom rails to the terminal posts (corner, end, and gate posts). They typically consist of a fitting that slides over the rail and attaches to the post with a bolt or set screw. Line rail end connectors are essential for maintaining the structural integrity of the fence and preventing sagging.

Brace Bands

Brace bands are used to secure the tension bands to the terminal posts. They wrap around the post and are bolted together, providing a strong and secure connection. Brace bands are crucial for tensioning the chain link fabric and preventing it from sagging or becoming loose. These are incredibly important chain link fence panel connectors.

Tension Bands

Tension bands are used to attach the chain link fabric to the terminal posts. They are spaced evenly along the post and are tightened to create tension in the fabric. Tension bands work in conjunction with brace bands to ensure a taut and secure fence. Without reliable tension bands, the entire fence structure can be compromised. Using high quality materials for these chain link fence panel connectors is essential.

Rail End Cups

Rail end cups, also called line post caps, connect the horizontal rails to the line posts. They provide a secure and aesthetically pleasing connection. They come in different sizes to match the diameter of the posts and rails. These chain link fence panel connectors are designed for ease of installation and long-term durability.

Sleeve Connectors

Sleeve connectors are used to join sections of top rail together. They slide inside the rail ends and are secured with set screws or crimping. Sleeve connectors provide a strong and seamless connection, ensuring that the top rail remains continuous and stable. Proper use of sleeve connectors prevents weak points in the top rail, enhancing the overall strength of the fence.

Materials Used in Chain Link Fence Panel Connectors

The material of the chain link fence panel connectors is as important as the design. The most common materials are:

Galvanized Steel

Galvanized steel is the most popular choice for chain link fence panel connectors due to its excellent corrosion resistance and strength. The galvanization process involves coating the steel with a layer of zinc, which protects it from rust and other forms of corrosion. Galvanized steel connectors are suitable for most environments and offer a good balance of cost and performance. Choosing galvanized steel chain link fence panel connectors will extend the life of your fence.

Aluminum

Aluminum connectors are lightweight and highly resistant to corrosion. They are a good choice for coastal areas or other environments where corrosion is a major concern. However, aluminum is not as strong as steel, so it may not be suitable for high-security applications. Aluminum chain link fence panel connectors are also more expensive than galvanized steel.

Stainless Steel

Stainless steel connectors offer the ultimate in corrosion resistance and strength. They are ideal for harsh environments where other materials would quickly corrode. However, stainless steel is also the most expensive option. Consider stainless steel chain link fence panel connectors for critical applications or areas with extreme weather conditions.

Powder-Coated Steel

Powder-coated steel connectors offer a combination of strength and aesthetics. The powder coating provides an extra layer of protection against corrosion and can be customized to match the color of the fence. Powder-coated chain link fence panel connectors are a good choice for residential applications where appearance is important.

Installation Techniques for Chain Link Fence Panel Connectors

Proper installation of chain link fence panel connectors is crucial for ensuring the stability and longevity of the fence. Here are some general guidelines:

- Preparation: Before starting the installation, gather all the necessary tools and materials. This includes the connectors, posts, rails, chain link fabric, tension bars, and hardware.

- Post Installation: Install the terminal posts (corner, end, and gate posts) first. Ensure that they are properly spaced and set in concrete for maximum stability.

- Rail Installation: Attach the line rail end connectors to the terminal posts and slide the top and bottom rails into the connectors. Secure the rails with bolts or set screws.

- Fabric Attachment: Attach the tension bands to the terminal posts and weave the tension bars through the chain link fabric. Use pliers to tighten the tension bands and secure the fabric to the posts.

- Final Adjustments: Make any necessary adjustments to ensure that the fence is straight and taut. Check all connections to ensure that they are secure.

Maintenance and Care of Chain Link Fence Panel Connectors

Even with high-quality chain link fence panel connectors, regular maintenance is essential for prolonging the life of the fence. Here are some tips:

- Inspect Regularly: Inspect the connectors regularly for signs of corrosion or damage. Replace any damaged connectors immediately.

- Clean Periodically: Clean the connectors periodically with a mild detergent and water to remove dirt and debris.

- Lubricate: Lubricate the bolts and set screws with a rust inhibitor to prevent corrosion and ensure easy removal.

- Tighten Connections: Check the tightness of the connections regularly and tighten any loose bolts or set screws.

Troubleshooting Common Issues with Chain Link Fence Panel Connectors

Even with careful installation and maintenance, some common issues can arise with chain link fence panel connectors:

Corrosion

Corrosion is a common problem, especially in coastal areas or other environments with high humidity. To prevent corrosion, use galvanized steel or stainless steel connectors and apply a rust inhibitor to the bolts and set screws. Replace any corroded connectors immediately to prevent further damage. [See also: Preventing Fence Corrosion]

Loose Connections

Loose connections can cause the fence to sag or become unstable. Check the tightness of the connections regularly and tighten any loose bolts or set screws. Use threadlocker to prevent the bolts from loosening over time. Properly installed chain link fence panel connectors should remain tight for years.

Damaged Connectors

Damaged connectors can compromise the integrity of the fence. Replace any damaged connectors immediately to prevent further damage. Use high-quality connectors that are designed to withstand the elements and physical stress. Consider the type of chain link fence panel connectors you purchase to ensure they are robust enough for the application.

Choosing the Right Chain Link Fence Panel Connectors for Your Project

Selecting the right chain link fence panel connectors is crucial for the success of your fence project. Consider the following factors:

- Material: Choose a material that is appropriate for your environment and budget. Galvanized steel is a good all-around choice, while aluminum and stainless steel offer superior corrosion resistance.

- Type: Select the appropriate type of connector for each application. Use line rail end connectors for attaching the rails to the terminal posts, brace bands for securing the tension bands, and tension bands for attaching the fabric to the posts.

- Size: Ensure that the connectors are the correct size for your posts and rails. Use a measuring tape to determine the diameter of the posts and rails and select connectors that match.

- Quality: Invest in high-quality connectors that are designed to withstand the elements and physical stress. Cheap connectors may fail prematurely, leading to costly repairs.

The Future of Chain Link Fence Panel Connectors

The technology and materials used in chain link fence panel connectors are constantly evolving. Manufacturers are developing new and improved connectors that are stronger, more durable, and easier to install. Some of the latest innovations include:

- Self-Locking Connectors: Self-locking connectors eliminate the need for bolts and set screws, making installation faster and easier.

- Composite Connectors: Composite connectors offer a combination of strength, corrosion resistance, and light weight.

- Smart Connectors: Smart connectors incorporate sensors that monitor the condition of the fence and alert you to any potential problems.

Conclusion

Chain link fence panel connectors are essential components that play a critical role in the stability and longevity of chain link fences. By understanding the different types of connectors, materials, installation techniques, and maintenance practices, you can ensure that your fence provides years of reliable service. Investing in high-quality connectors and following the guidelines outlined in this guide will help you create a fence that is both secure and aesthetically pleasing. Remember to regularly inspect your chain link fence panel connectors and address any issues promptly to maintain the integrity of your fence. [See also: Chain Link Fence Maintenance Tips]