Acrylic Chemical Compatibility Chart: A Comprehensive Guide

Understanding the chemical compatibility of acrylic is crucial in various industries, from manufacturing and construction to healthcare and research. Acrylic, also known as polymethyl methacrylate (PMMA), is a versatile thermoplastic renowned for its transparency, impact resistance, and ease of fabrication. However, its susceptibility to certain chemicals necessitates careful consideration when selecting materials for specific applications. This comprehensive guide delves into the acrylic chemical compatibility chart, providing essential information for engineers, designers, and anyone working with acrylic materials.

This guide aims to provide a clear and accessible resource on the acrylic chemical compatibility chart. We will explore the factors influencing chemical resistance, interpret the chart, highlight common compatible and incompatible chemicals, and offer practical tips for selecting the right acrylic for your project. By understanding these principles, you can ensure the longevity and performance of your acrylic components.

What is Acrylic?

Acrylic, or PMMA, is a synthetic polymer known for its exceptional clarity, weather resistance, and rigidity. It’s commonly used as a lightweight or shatter-resistant alternative to glass. Acrylic is available in various forms, including sheets, rods, tubes, and resins, making it adaptable to diverse applications.

- Properties: High transparency, good impact strength, UV resistance, and relatively low cost.

- Applications: Windows, signage, aquariums, lenses, medical devices, and automotive parts.

Factors Influencing Acrylic Chemical Resistance

The chemical resistance of acrylic depends on several factors, including:

- Chemical Concentration: Higher concentrations generally increase the likelihood of degradation.

- Exposure Time: Prolonged exposure to a chemical can weaken the acrylic structure.

- Temperature: Elevated temperatures can accelerate chemical reactions and reduce resistance.

- Stress Levels: Mechanical stress can make acrylic more vulnerable to chemical attack.

- Type of Acrylic: Different formulations of acrylic may exhibit varying levels of chemical resistance.

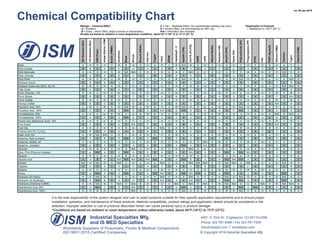

Understanding the Acrylic Chemical Compatibility Chart

An acrylic chemical compatibility chart is a reference tool that indicates how acrylic reacts to different chemicals. These charts typically categorize chemicals based on their effect on acrylic:

- A (Excellent): No noticeable effect. Acrylic can be used safely with the chemical.

- B (Good): Minor effect, such as slight swelling or discoloration. May be acceptable for certain applications.

- C (Fair): Moderate effect, including significant swelling, softening, or cracking. Use is not recommended for critical applications.

- D (Poor): Severe degradation. Acrylic is not compatible with the chemical.

It’s important to note that these ratings are based on specific test conditions and may vary depending on the factors mentioned earlier. Always consult the manufacturer’s data sheet for the most accurate information.

How to Read an Acrylic Chemical Compatibility Chart

The acrylic chemical compatibility chart is usually organized in a table format. The left column lists various chemicals, while the top row indicates the compatibility rating (A, B, C, or D). To determine the compatibility of acrylic with a specific chemical, locate the chemical in the left column and find the corresponding rating in the appropriate column. For example, if acetic acid has a rating of ‘B’, it suggests acrylic might be suitable for short-term or non-critical applications involving acetic acid.

Common Compatible Chemicals

Acrylic exhibits good resistance to a range of chemicals, including:

- Water: Acrylic is generally unaffected by water exposure.

- Diluted Acids: Weak acids like dilute hydrochloric acid have minimal impact.

- Aliphatic Hydrocarbons: Mineral oil and paraffin are typically compatible.

- Salt Solutions: Many salt solutions do not significantly affect acrylic.

Common Incompatible Chemicals

Certain chemicals can severely damage acrylic, leading to cracking, crazing, or dissolution. These include:

- Strong Acids: Concentrated sulfuric acid and nitric acid can degrade acrylic.

- Ketones: Acetone and methyl ethyl ketone (MEK) will dissolve or soften acrylic.

- Aromatic Hydrocarbons: Toluene and benzene can cause swelling and cracking.

- Chlorinated Solvents: Chloroform and methylene chloride can damage acrylic.

- Alcohols: While some alcohols have a minor effect, prolonged exposure to certain alcohols can cause damage.

Examples of Acrylic Chemical Compatibility

Here are a few examples to illustrate how to use the acrylic chemical compatibility chart:

- Scenario 1: Designing a transparent enclosure for a laboratory experiment involving a dilute sodium hydroxide solution. According to the chart, acrylic has good resistance to dilute bases, making it a suitable material.

- Scenario 2: Selecting a material for a gauge cover in a chemical processing plant where acetone is present. The chart indicates that acetone is incompatible with acrylic, so an alternative material like polycarbonate or glass should be considered.

- Scenario 3: Manufacturing outdoor signage that will be exposed to rainwater and sunlight. The chart shows that acrylic is resistant to water and UV radiation, making it an excellent choice.

Practical Tips for Selecting Acrylic

When selecting acrylic for an application, consider these practical tips:

- Consult the Acrylic Chemical Compatibility Chart: Always refer to a reliable chart to assess the compatibility of acrylic with the chemicals involved.

- Consider Environmental Factors: Account for temperature, humidity, and UV exposure.

- Test Before Deployment: Conduct small-scale tests to verify compatibility under actual operating conditions.

- Choose the Right Grade: Select an acrylic grade formulated for specific chemical resistance requirements.

- Apply Protective Coatings: Consider using coatings to enhance chemical resistance.

Specific Applications and Chemical Resistance

Different applications require different levels of chemical resistance. Let’s examine how the acrylic chemical compatibility chart can guide material selection in a few specific scenarios:

Medical Devices

Acrylic is used in various medical devices due to its biocompatibility and clarity. However, sterilization processes often involve chemicals. Ensure the selected acrylic grade is compatible with sterilizing agents like ethylene oxide or hydrogen peroxide. The acrylic chemical compatibility chart is essential in verifying this.

Automotive Industry

Acrylic is used for tail light lenses and interior components. It must withstand exposure to gasoline, oils, and cleaning agents. Careful review of the acrylic chemical compatibility chart is critical to avoid material degradation and ensure long-term performance.

Aquariums

Large aquariums often use acrylic for its high transparency and strength. While acrylic is generally resistant to water, additives in the water, such as chlorine or pH adjusters, can affect its longevity. Regular monitoring and appropriate water treatment are necessary.

Signage

Outdoor signage made from acrylic must withstand weathering and potential exposure to cleaning solvents or graffiti removers. Selecting an acrylic grade with good UV resistance and chemical resistance is essential for maintaining its appearance and structural integrity.

Advanced Considerations

For critical applications, consider these advanced factors:

- Stress Cracking: Some chemicals can induce stress cracking in acrylic, especially under load.

- Plasticizers: Certain plasticizers in acrylic can leach out upon exposure to chemicals, altering its properties.

- Long-Term Exposure: The acrylic chemical compatibility chart typically provides short-term data. Long-term exposure may have cumulative effects.

Alternative Materials

If acrylic is not compatible with the chemicals in your application, consider alternative materials such as:

- Polycarbonate: Offers higher impact resistance and broader chemical resistance than acrylic.

- Polypropylene: Excellent resistance to many chemicals, but lower transparency.

- PTFE (Teflon): Exceptional chemical resistance, but more expensive.

- Glass: Inert to most chemicals, but more brittle than acrylic.

[See also: Polycarbonate Chemical Compatibility Guide]

Conclusion

The acrylic chemical compatibility chart is an indispensable tool for anyone working with acrylic materials. By understanding the factors influencing chemical resistance, interpreting the chart, and considering specific application requirements, you can make informed decisions that ensure the long-term performance and reliability of your acrylic components. Remember to always consult the manufacturer’s data sheets and conduct thorough testing before deploying acrylic in critical applications. Prioritizing material compatibility will lead to safer, more durable, and cost-effective solutions.

Ultimately, choosing the right material involves careful consideration of all factors, including the chemical environment, operating conditions, and desired performance characteristics. Leveraging the acrylic chemical compatibility chart effectively helps to make this selection process more informed and efficient.