Cerakote Finish on Guns: A Comprehensive Guide

The application of a Cerakote finish on guns has become increasingly popular among firearm enthusiasts, competitive shooters, and law enforcement professionals alike. This ceramic-based coating offers a superior alternative to traditional firearm finishes, providing enhanced durability, corrosion resistance, and aesthetic customization. This comprehensive guide will delve into the intricacies of Cerakote finishes on guns, exploring its benefits, application process, and various considerations for gun owners.

What is Cerakote?

Cerakote is a Polymer-Ceramic Composite coating that can be applied to metals, plastics, polymers, and wood. Unlike traditional coatings like bluing or Parkerizing, Cerakote offers a thin-film coating that’s remarkably durable. It’s renowned for its abrasion resistance, corrosion resistance, chemical resistance, impact strength, and hardness. This makes it an ideal choice for firearms, which are often subjected to harsh conditions and demanding use.

Benefits of Cerakote Finish on Guns

Choosing a Cerakote finish for your firearm offers several advantages:

- Enhanced Durability: Cerakote provides exceptional protection against scratches, abrasions, and wear, extending the lifespan of your firearm.

- Corrosion Resistance: Cerakote is highly resistant to rust and corrosion, even in harsh environments. This is crucial for firearms that may be exposed to moisture, saltwater, or other corrosive elements.

- Chemical Resistance: The coating is resistant to a wide range of chemicals, including solvents, oils, and cleaning agents, ensuring that your firearm’s finish remains intact.

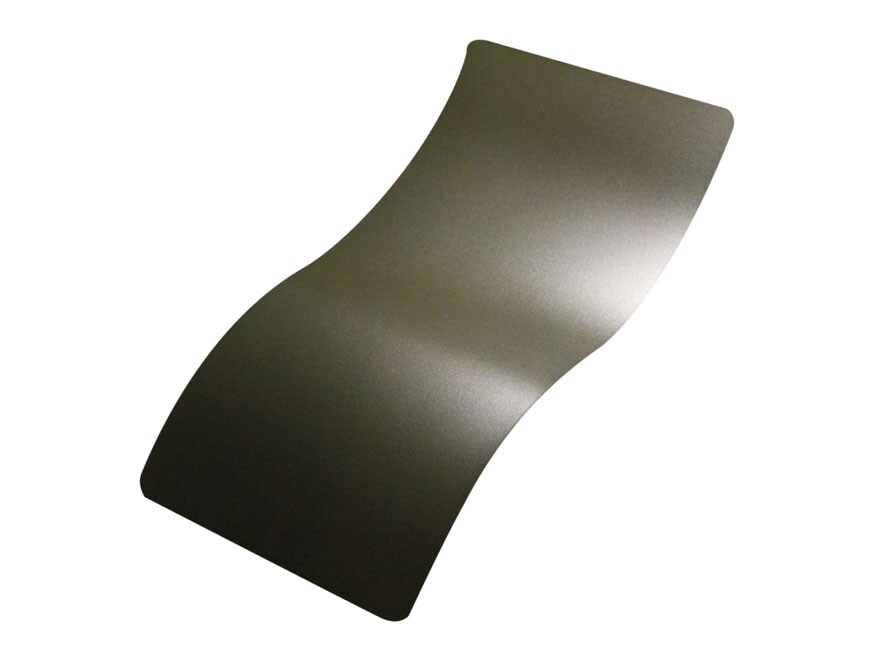

- Customization Options: Cerakote is available in a wide array of colors and finishes, allowing for personalized customization of your firearm’s appearance. You can choose from solid colors, camouflage patterns, or even custom designs.

- Thin Film Application: Unlike some other coatings, Cerakote is applied in a thin film, typically around 0.001 inches thick. This minimal thickness ensures that it doesn’t interfere with the firearm’s function or tolerances.

- Improved Performance: By reducing friction and wear, Cerakote can contribute to smoother operation and improved performance of your firearm.

The Cerakote Application Process

Applying Cerakote to a firearm is a multi-step process that requires specialized equipment and expertise. It’s generally recommended to have the application performed by a certified Cerakote applicator to ensure a high-quality and durable finish.

Preparation

The first step in the Cerakote application process is thorough preparation of the firearm components. This typically involves disassembling the firearm, degreasing all parts to be coated, and media blasting to create a surface profile that will allow the Cerakote to properly adhere. The media blasting process is crucial for creating a mechanical bond between the coating and the substrate.

Masking

Areas of the firearm that should not be coated, such as the bore, internal components, and certain markings, are carefully masked off. This ensures that the Cerakote is only applied to the intended surfaces.

Application

The Cerakote is then applied using a specialized spray gun. The applicator will apply multiple thin coats to achieve the desired thickness and coverage. The application process requires precise control and technique to ensure a uniform and consistent finish.

Curing

After application, the coated parts are cured in an oven at a specific temperature for a set period of time. The curing process hardens the Cerakote and bonds it to the substrate, creating a durable and long-lasting finish. The specific curing temperature and time will vary depending on the type of Cerakote being used.

Reassembly

Once the parts have cooled, the masking is removed, and the firearm is carefully reassembled. The completed firearm now boasts a durable, corrosion-resistant, and aesthetically pleasing Cerakote finish.

Types of Cerakote Finishes

Cerakote offers a variety of finish options to suit different needs and preferences:

- H-Series: The most common type of Cerakote, offering a balance of durability, corrosion resistance, and color options. Ideal for general-purpose firearms.

- Elite Series: Designed for maximum performance in extreme environments, offering superior hardness, abrasion resistance, and chemical resistance. Suitable for high-use firearms and those exposed to harsh conditions.

- C-Series: A high-temperature coating designed for exhaust systems and other components that experience extreme heat. While not typically used on the main body of a firearm, it can be applied to suppressors or other heat-generating accessories.

- Micro Slick Dry Film Lubricant: Designed to reduce friction and improve the performance of moving parts. Can be applied to internal components such as bolt carriers and triggers.

Considerations When Choosing a Cerakote Finish on Guns

Before opting for a Cerakote finish on your gun, consider the following factors:

- Cost: Cerakote application can be more expensive than traditional firearm finishes. However, the enhanced durability and performance may justify the cost for many gun owners.

- Applicator Expertise: The quality of the Cerakote finish depends heavily on the skill and experience of the applicator. Choose a certified Cerakote applicator with a proven track record.

- Preparation is Key: Proper preparation of the firearm components is essential for a successful Cerakote application. Ensure that the applicator uses proper degreasing and media blasting techniques.

- Color and Finish Selection: Consider the intended use of the firearm and choose a color and finish that meets your needs and preferences. Factors such as concealment, aesthetics, and environmental conditions should be taken into account.

- Warranty: Inquire about the applicator’s warranty policy in case of defects or issues with the Cerakote finish.

Maintaining Your Cerakote Finish

While Cerakote is highly durable, proper maintenance can help extend its lifespan and maintain its appearance. Here are some tips for caring for your Cerakote finish:

- Clean Regularly: Clean your firearm regularly with a mild solvent and a soft cloth. Avoid using abrasive cleaners or brushes that could scratch the finish.

- Lubricate Properly: Use a high-quality gun oil to lubricate moving parts. Avoid getting oil on the Cerakote finish, as it can attract dirt and debris.

- Avoid Harsh Chemicals: Avoid using harsh chemicals or solvents that could damage the Cerakote finish.

- Store Properly: Store your firearm in a dry and safe place to prevent rust and corrosion.

Cerakote vs. Other Firearm Finishes

Cerakote stands out from other firearm finishes due to its superior properties. Compared to bluing, Parkerizing, or traditional paints, Cerakote offers better corrosion resistance, scratch resistance, and overall durability. While other coatings might be cheaper upfront, Cerakote’s longevity and performance provide greater value in the long run. [See also: Firearm Coating Comparison: Cerakote vs. Bluing]

Common Misconceptions About Cerakote on Guns

There are several misconceptions surrounding Cerakote finishes on guns. One common myth is that Cerakote is indestructible. While incredibly durable, it’s not impervious to damage. Another misconception is that all Cerakote applications are equal. The quality varies significantly based on applicator skill and preparation. It is crucial to choose a reputable applicator. [See also: Choosing a Cerakote Applicator]

The Future of Cerakote in the Firearm Industry

Cerakote continues to evolve, with new formulations and application techniques being developed. Its versatility and performance ensure its continued popularity in the firearm industry. As technology advances, we can expect even more innovative Cerakote solutions for firearm protection and customization. The demand for Cerakote finish on guns is expected to grow as more gun owners recognize its benefits. [See also: Future Trends in Firearm Coatings]

Conclusion

A Cerakote finish on guns offers a significant upgrade in terms of durability, corrosion resistance, and aesthetic customization. While the application process requires expertise and may be more expensive than traditional finishes, the long-term benefits make it a worthwhile investment for many firearm owners. By understanding the properties of Cerakote, the application process, and the considerations involved, you can make an informed decision about whether a Cerakote finish is right for your firearm. Investing in a Cerakote finish on guns is investing in the longevity and performance of your firearm.