Understanding AR-15 Barrel Threads: A Comprehensive Guide

The AR-15 platform is renowned for its modularity and versatility, allowing users to customize nearly every aspect of the rifle. A critical component in this customization process is the barrel, and understanding AR-15 barrel threads is paramount for anyone looking to upgrade or replace their existing barrel. This guide delves into the intricacies of AR-15 barrel threads, covering everything from thread types and specifications to installation considerations and potential compatibility issues.

Why Understanding AR-15 Barrel Threads Matters

The barrel thread ar 15 is more than just a connection point; it’s a crucial interface that affects the rifle’s accuracy, reliability, and overall performance. Incorrectly matching threads can lead to serious problems, including damage to the receiver, inaccurate shooting, and even dangerous malfunctions. Whether you’re a seasoned gunsmith or a first-time AR-15 owner, a solid understanding of AR-15 barrel threads is essential.

The Role of Barrel Threads in Accuracy

A properly installed barrel, secured with correctly matched barrel threads ar 15, ensures consistent alignment between the barrel and the receiver. This alignment is vital for maintaining accuracy, as it minimizes vibrations and ensures that the bullet travels down the barrel in a predictable manner. Conversely, loose or mismatched threads can introduce play and inconsistencies, negatively impacting accuracy.

Ensuring Safe Operation

Using the wrong barrel thread ar 15 can compromise the structural integrity of your AR-15. Forcing a barrel with incompatible threads can damage both the barrel and the receiver, potentially leading to catastrophic failure during firing. Always verify the thread specifications before attempting to install a new barrel.

Common AR-15 Barrel Thread Specifications

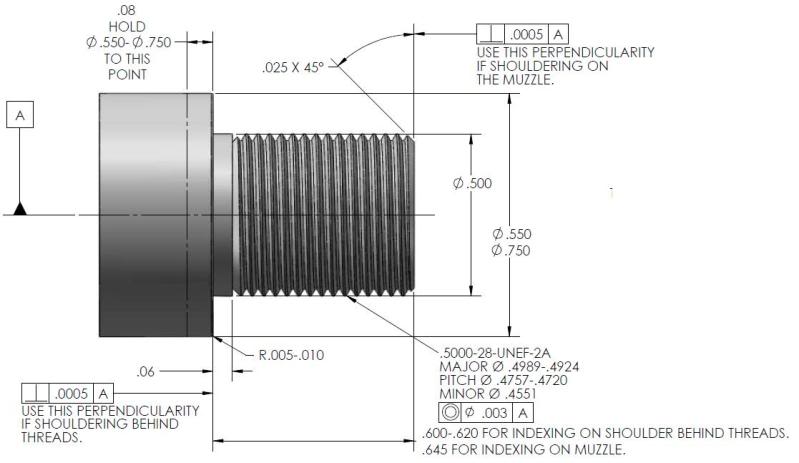

The most common AR-15 barrel thread specification is 1-1/8″-16 UN. Let’s break down what each part of this specification means:

- 1-1/8″: This refers to the nominal diameter of the thread, which is 1.125 inches.

- 16: This indicates the number of threads per inch (TPI). In this case, there are 16 threads per inch.

- UN: This stands for Unified National thread form, a standard thread profile used in the United States.

While 1-1/8″-16 UN is the most prevalent, some variations exist, particularly in specialized AR-15 builds. Always confirm the specific thread requirements for your receiver and barrel.

Understanding Thread Pitch and Diameter

Thread pitch, measured in threads per inch (TPI), and diameter are the two key parameters that define a thread. Mismatched pitch or diameter will prevent proper engagement and can lead to damage. Using a thread gauge and calipers can help you accurately identify the barrel thread ar 15 specifications.

Tools and Techniques for Identifying AR-15 Barrel Threads

Properly identifying AR-15 barrel threads requires the right tools and techniques. Here are some essential items:

- Thread Gauge: A thread gauge, also known as a thread pitch gauge, is a tool with a series of precisely cut leaves, each corresponding to a specific thread pitch. By matching the leaves to the threads on the barrel, you can determine the TPI.

- Calipers: Calipers are used to measure the diameter of the thread. Digital calipers provide the most accurate readings.

- Thread Identification Charts: These charts provide a visual reference for different thread types and sizes. They can be helpful in narrowing down the possibilities.

Step-by-Step Thread Identification Process

- Visually Inspect the Threads: Look for any signs of damage or wear. Clean the threads thoroughly before proceeding.

- Measure the Diameter: Use calipers to measure the outside diameter of the threads.

- Determine the Thread Pitch: Use a thread gauge to determine the TPI. Try different leaves until you find one that fits snugly into the threads without any gaps.

- Consult Thread Identification Charts: Compare your measurements to the charts to confirm the thread type.

Installing an AR-15 Barrel: A Step-by-Step Guide

Installing an AR-15 barrel requires careful attention to detail and the proper tools. Here’s a general guide, but always consult your rifle’s manual and seek professional assistance if needed:

- Ensure the Rifle is Unloaded and Safe: This is the most critical step. Verify that the magazine is removed, the chamber is empty, and the firearm is pointed in a safe direction.

- Disassemble the Upper Receiver: Remove the handguard, gas tube, and any other components obstructing access to the barrel nut.

- Remove the Old Barrel Nut: Use a barrel nut wrench to loosen and remove the old barrel nut. Be careful not to damage the receiver.

- Apply Grease to the Receiver Threads: Apply a thin layer of high-quality grease to the AR-15 barrel threads on the receiver. This will facilitate smooth installation and prevent seizing.

- Install the New Barrel: Insert the new barrel into the receiver, ensuring that the gas port is aligned correctly.

- Install the New Barrel Nut: Thread the new barrel nut onto the receiver.

- Torque the Barrel Nut to Specification: Use a torque wrench to tighten the barrel nut to the manufacturer’s specified torque. This is a critical step, as over- or under-tightening can damage the receiver or affect accuracy. Typically, the torque specification is between 30 and 80 foot-pounds.

- Align the Gas Tube Hole: Ensure that the gas tube hole in the barrel nut aligns with the gas tube port in the receiver. You may need to adjust the barrel nut slightly to achieve proper alignment.

- Reinstall the Gas Tube and Handguard: Reinstall the gas tube and handguard.

- Perform a Function Check: Perform a function check to ensure that the rifle is operating correctly.

The Importance of Proper Torque

Proper torque is crucial when installing an AR-15 barrel. Under-torquing can lead to the barrel loosening during firing, while over-torquing can damage the receiver threads. Always use a calibrated torque wrench and follow the manufacturer’s specifications. [See also: Choosing the Right AR-15 Barrel Nut Wrench]

Troubleshooting Common AR-15 Barrel Thread Issues

Even with careful installation, issues can arise with AR-15 barrel threads. Here are some common problems and their potential solutions:

- Cross-Threading: Cross-threading occurs when the threads are not properly aligned during installation, causing them to bind and potentially damage the threads. If you encounter resistance, stop immediately and realign the threads.

- Thread Damage: Damaged threads can prevent proper engagement and affect accuracy. Minor damage can sometimes be repaired with a thread chaser, but severe damage may require replacing the barrel or receiver.

- Seizing: Seizing occurs when the threads become stuck together due to corrosion or lack of lubrication. Applying penetrating oil and using a thread chaser can often resolve this issue.

When to Seek Professional Help

If you’re uncomfortable with any aspect of barrel installation or troubleshooting, it’s always best to seek professional help from a qualified gunsmith. They have the expertise and tools necessary to ensure proper installation and prevent potential damage.

Selecting the Right AR-15 Barrel for Your Needs

Choosing the right AR-15 barrel involves considering several factors beyond just the barrel thread ar 15. These factors include:

- Barrel Length: Barrel length affects the rifle’s overall weight, maneuverability, and ballistic performance. Shorter barrels are more maneuverable, while longer barrels offer greater accuracy and velocity.

- Barrel Material: Common barrel materials include chrome-moly vanadium steel and stainless steel. Chrome-moly barrels are more durable and resistant to wear, while stainless steel barrels offer greater accuracy.

- Barrel Twist Rate: Twist rate refers to the number of inches it takes for the rifling inside the barrel to complete one full rotation. Different twist rates are optimized for different bullet weights and lengths.

- Barrel Profile: Barrel profile refers to the shape and thickness of the barrel. Different profiles offer different balances of weight, stiffness, and heat dissipation.

Matching Barrel Threads to Your Receiver

Before purchasing a new barrel, always verify that the barrel thread ar 15 matches your receiver. Using incompatible threads can damage both components and compromise the rifle’s safety and performance. [See also: AR-15 Upper Receiver Compatibility Guide]

The Future of AR-15 Barrel Threads

While the 1-1/8″-16 UN AR-15 barrel thread specification remains the industry standard, advancements in materials and manufacturing techniques may lead to new thread designs in the future. These new designs could offer improved strength, accuracy, or ease of installation. As the AR-15 platform continues to evolve, it’s important to stay informed about the latest developments in barrel technology.

Conclusion

Understanding AR-15 barrel threads is crucial for anyone looking to customize or maintain their AR-15. By understanding the different thread specifications, using the right tools and techniques, and following proper installation procedures, you can ensure the safe and reliable operation of your rifle. Remember to always prioritize safety and seek professional help when needed. The correct barrel thread ar 15 ensures accuracy and safety. Always double-check that the barrel thread ar 15 matches your receiver. Understanding AR-15 barrel threads is key to a successful build. The barrel thread ar 15 is a critical component. Always handle AR-15 barrel threads with care. Choosing the correct barrel thread ar 15 is essential. Mismatched barrel thread ar 15 can be dangerous. Proper AR-15 barrel thread installation is vital. The barrel thread ar 15 requires precision. Know your AR-15 barrel threads. The barrel thread ar 15 is a standard size for most AR-15s. When replacing a barrel, match the barrel thread ar 15. For customization, understanding AR-15 barrel threads opens possibilities. The barrel thread ar 15 is more than just a connection; it’s critical.